Easy Title 24 Ventilation Requirement Compliance

IAQ and Efficiency Under Title 24

The 2022 update to California Title 24 is now in effect, and developers and facility managers may be wondering how their upcoming projects will comply. Our last two blog posts on Title 24 HVAC requirements covered rule changes for economizer controls and setback modes based on building occupancy, and outlined how to meet them affordably. Review that information here and here.

In this post, we’ll talk about expanded requirements for demand-controlled ventilation (DCV). Previous releases of Title 24 have required DCV in only certain types of buildings, but in the 2022 edition, the number of buildings required to utilize a minimum fresh air rate using DCV goes up. Where the 2019 edition of Title 24 specifies DCV rates for buildings such as daycares, theaters, and public assembly spaces, the newest code now includes fitness centers, retail stores, dance clubs, and more. This change is likely due to the COVID-19 pandemic, when scientific understanding of fresh air ventilation and its importance to indoor air quality (IAQ) jumped from basic comfort and occupant productivity to actively helping reduce the spread of illness.

What does ventilation and IAQ have to do with energy efficiency? Why would it be included in an energy efficiency code? DCV is at the heart of top priorities in the commercial buildings space after the COVID-19 pandemic: the intersection of optimal IAQ for occupant health and productivity and energy efficiency. Read on to learn what DCV means for these two things in commercial buildings, and how to implement it easily and affordably.

Why Air Quality in an Energy Code?

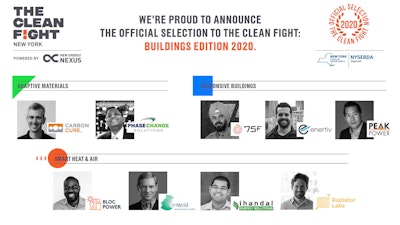

Studies like this one from Harvard's T.H. Chan School of Public Health show that adequate ventilation and air quality are vital to cognitive function, productivity, and comfort. Now, ventilation is also linked to slowing the spread of airborne illnesses. The American Society for Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE) has set forth standards for ventilation both in and out of a pandemic setting, which 75F has covered in detail.

Despite the documented health benefits associated with better ventilation rates, many building operators are hesitant to follow through with this guidance due to the amount of energy required to clean and condition outside air. According to the journal article “COVID-19 Impact on Operation and Energy Consumption of Heating, Ventilation and Air-Conditioning (HVAC) Systems” in the National Library of Medicine, “increasing the minimum outdoor air rate from 2.5 L/(s∙person) to 10 L/(s∙person) will increase the operation costs of HVAC systems by 2 to 10 percent.”

Under Title 24 ventilation requirements, outside air levels in occupied spaces are conditional based on various factors. Check the code to see what fresh air level requirements your building may need to meet. Meanwhile, DCV is an important strategy to keep energy use in check while maintaining or exceeding air quality requirements in commercial buildings.

Implementing DCV Using IoT

DCV uses CO₂ levels in the air to understand the occupancy and ventilation needs of each zone in a building, adjusting the ventilation rate in occupied spaces in an incremental way. This is based on either the return air CO₂, or a trim and respond system for zone-level DCV. Rather than ventilating all building spaces equally, the optimization of outside air comes from these preconfigured sequences which redirect air where it is needed for temperature or ventilation, reducing preventative and unplanned maintenance costs and reducing energy costs, all while measurably improving comfort and IAQ.

To accomplish this, building operators will need to add CO₂ monitoring to their building or portfolio and have a building automation system (BAS) connected to the outside air damper. Traditional BAS providers can accomplish this and other Title 24 HVAC requirements, but they are often expensive, complicated, and labor-intensive to install and maintain.

Most manufactured products do not offer CO₂ sensing packaged into a unit, so building owners will need to purchase a separate sensor for each zone — or more — to cover the required space between sensors. These additions are often pricey and will need to be integrated into an existing control system and its wired communication protocol, adding to labor costs.

The IoT-based approach to the BAS introduces a cost-effective path to following Title 24 ventilation requirements. With comprehensive sensing capabilities and no need for communications wire or custom programming, IoT-based controls are fast, effective, and affordable to install.

For example, 75F’s HyperStat has eight onboard air quality sensors, including CO₂. The device comes with an output that allows direct OA damper control and uses pre-made sequences of operation, saving significant engineering and installation labor hours.

Inherent cloud access and minute-by-minute data points mean the IoT-based BAS can easily perform DCV while simultaneously providing remote access and control, plus real-time alerts and analytics.