What is California Title 24, and Why do HVAC Economizers Matter?

What is Title 24?

The California Energy Code — commonly called Title 24 — is a set of regulations the California Building Standards Commission created in 1978 to cut down energy waste in the state. Title 24 dictates how contractors and facility managers select and install windows and doors, lighting, HVAC equipment, and other energy-influencing factors in both new construction and existing buildings.

Despite its origins in the ‘70s, Title 24 regulations are far from dated. The commission updates the energy code every three years, and these ongoing changes based on growing understanding of energy efficiency strategies help keep California’s energy consumption in check through population and building growth. According to the commission, the state’s current per-capita energy use is nearly the same as it was in ’78 despite an 80 percent economic increase.

Title 24’s latest update came out in 2022, and it includes notable changes for HVAC equipment selection and operation. Effective January 2023, contractors and facility managers with new-build projects or renovations spanning most retrofits will need to be familiar with these changes and make sure their projects comply.

In this blog post, we dive into one of the most significant Title 24 HVAC requirements update: All single-zone units three tons and above now need working economizers with fault detection and diagnostics. Read on to learn why working economizers present a challenge, what they can do when functioning properly, and how Internet of Things (IoT)-based building automation makes the path to functional and smart economizer control simple and affordable.

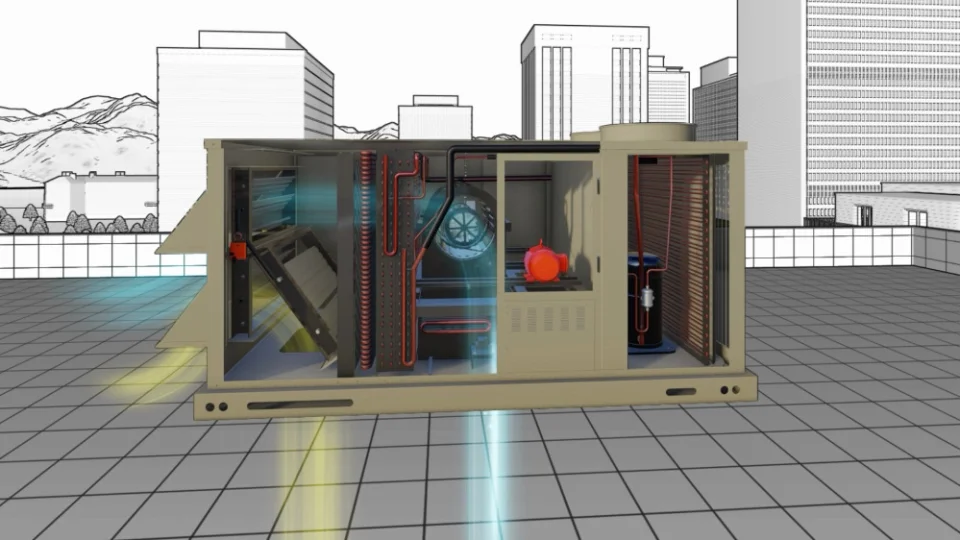

The Rooftop Economizer and its Deadbeat Alter Ego

Economizers are mechanical vents attached to the side of a rooftop unit (RTU), and they facilitate multiple important functions. When the air outside of a building is cool enough, economizers draw in fresh air to cool a space, thus reducing the energy required to condition hot indoor air. With building controls installed, economizers are also the mechanism for advanced sequences of operation such as Demand-Control Ventilation (DCV), which introduces fresh air based on current CO₂ levels instead of defaulting to the industry standard for fresh air levels all the time, reducing the need for conditioned air in unoccupied zones.

With intelligent control, the economizer can provide significant efficiency and comfort improvements in commercial buildings. Why, then, would Title 24 HVAC requirements need to include functional economizers in its latest update? Shouldn’t most buildings be taking advantage of economizers already?

The catch: Most economizers don’t work.

According to a New Buildings Institute analysis of 500 RTUs, economizers are either non-functional or problematic nearly 70 percent of the time. The reason for this varies — frozen outside air (OA) dampers, bad control settings, improper wiring, or malfunctioning return air or OA sensors could all be the culprit.

Fixing the fatal problem with an economizer is complicated and expensive without remote fault detection and diagnosticsbecause many facility managers don’t know their economizer isn’t working. There are no obvious signs within the building that point to a broken economizer — no dramatic temperature swings, burst pipes, or strange noises. Just higher operational costs, shortened equipment life, and poor indoor air quality.

Before the latest Title 24 HVAC requirement update and without experiencing the lower utility bills free cooling and DCV spurs, it may have been easier for developers or facility managers to disregard broken economizers. Now, however, they will need to take control of the deadbeat economizer and make it do its job. Where to start?

Here’s how IoT makes this facet of Title 24 compliance easy.

Title 24 Compliance for Economizers Using IoT

An IoT-based approach to economizer control introduces clarity and simplicity in what is usually a muddled, complicated, and ineffective process. Where an economizer relying on the RTU’s original equipment manufacturer (OEM) basic controller leaves facility managers blind and out of control, IoT provides invaluable real-time insight and control. Most importantly it guarantees function, and if that function is in jeopardy, facility managers will know.

75F® Outside Air Optimization™(OAO) is an IoT-based application designed to reach this end. It wields the economizer in the most effective way possible given weather and real-time conditions in a building to increase comfort and save energy simultaneously. It combines secure, cloud-connected hardware and pre-packaged software to accomplish this. 75F's OAO solution for effective economizer control can deliver total energy savings of 12 percent a year. Smaller customers see savings of up to 33 percent with modulating control.

And, when OA dampers freeze shut or something else goes awry, 75F’s system will automatically alert facility managers via email or text. Checking these alerts and diagnosing the issue is as easy as logging into the user portal, 75F® Facilisight™, where all your building’s real-time data is available from wherever you have Internet.

Functioning economizers aren't all that's new in Title 24's HVAC requirements. Next, we will cover Auto Away and Auto Force-Occupied control sequences needed to comply with the standard.